Stocktaking, or inventory counting, is a crucial process for any business that holds physical stock. Accurate stock data is essential for production planning, sales order fulfillment, and financial reporting. Sage X3 provides robust tools to manage this process efficiently. This article will guide you through a typical stock count session in Sage X3.

1. Preparation is Key:

- Define your Counting Scope: Determine which sites, warehouses, or specific items will be included in the stock count.

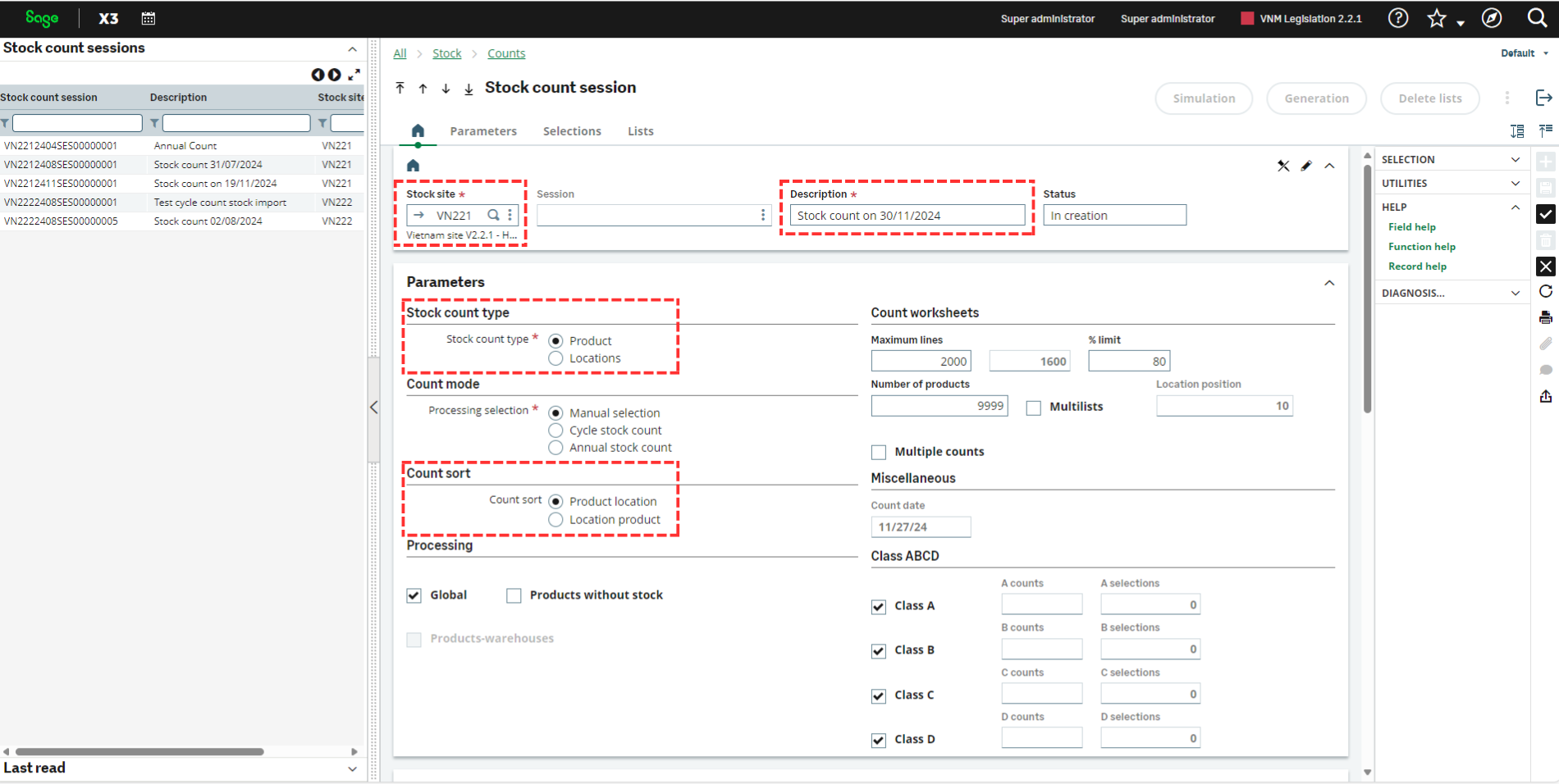

- Create Counting Plans: In Sage X3, you can create specific counting plans that outline the details of your stocktake. This includes:

- Plan ID (Session): A unique identifier for your stock count.

- Description: A clear description of the plan’s purpose (e.g., “Year-End Stocktake”).

- Site and Locations: Specify the areas to be counted.

- Items: Define the specific items or product families to include.

- Counting Methods (Counting Mode): Choose between “Full Physical Inventory” (counting all items) or “Cycle Counting” (counting specific items regularly).

- Train your Teams: Ensure your counting teams understand the process, the use of any scanning equipment, and the importance of accuracy.

- Prepare the Physical Area: Organize the warehouse or stock areas to facilitate easy counting. This may involve pre-counting some items or clearing obstructions.

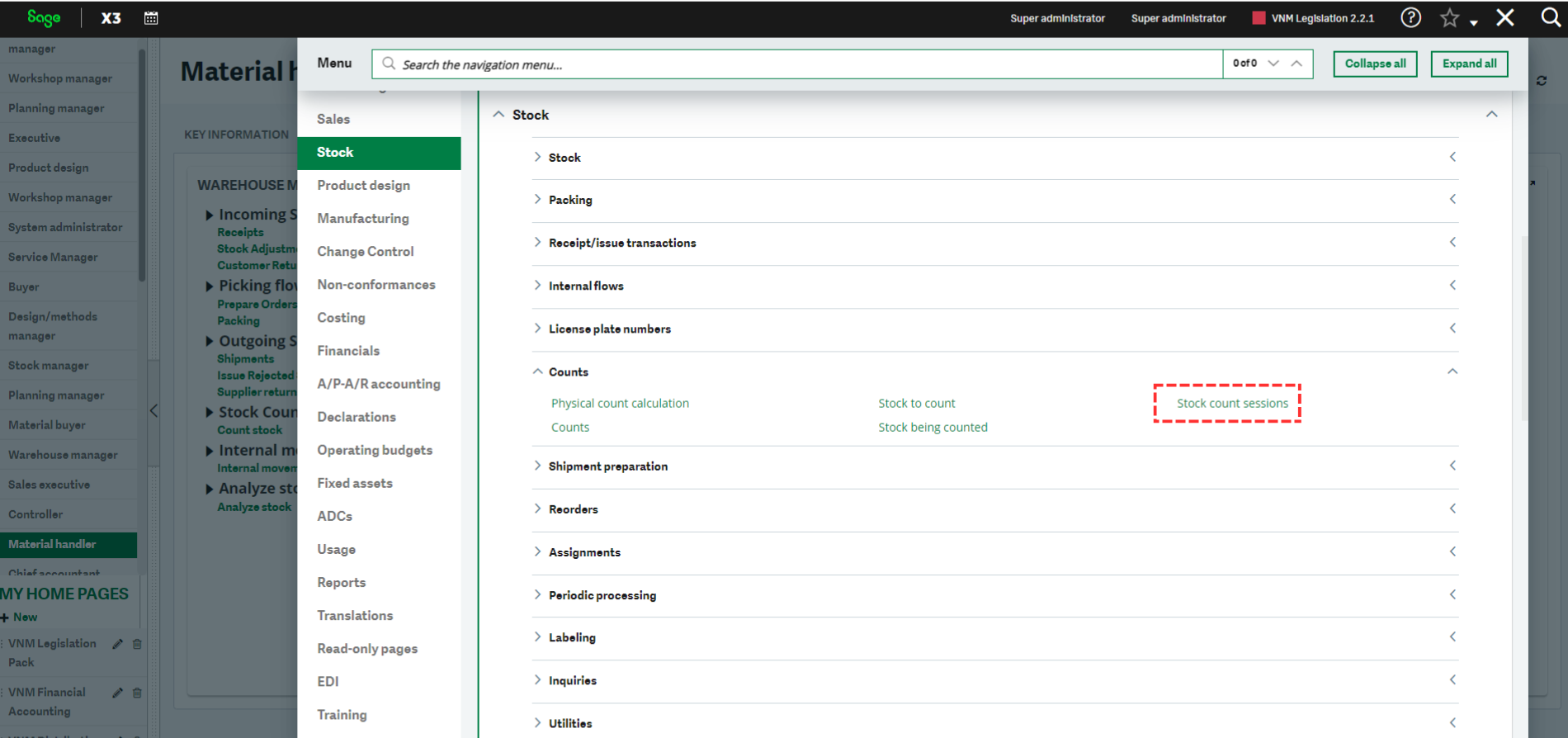

2. Initiate the Stock Count in Sage X3:

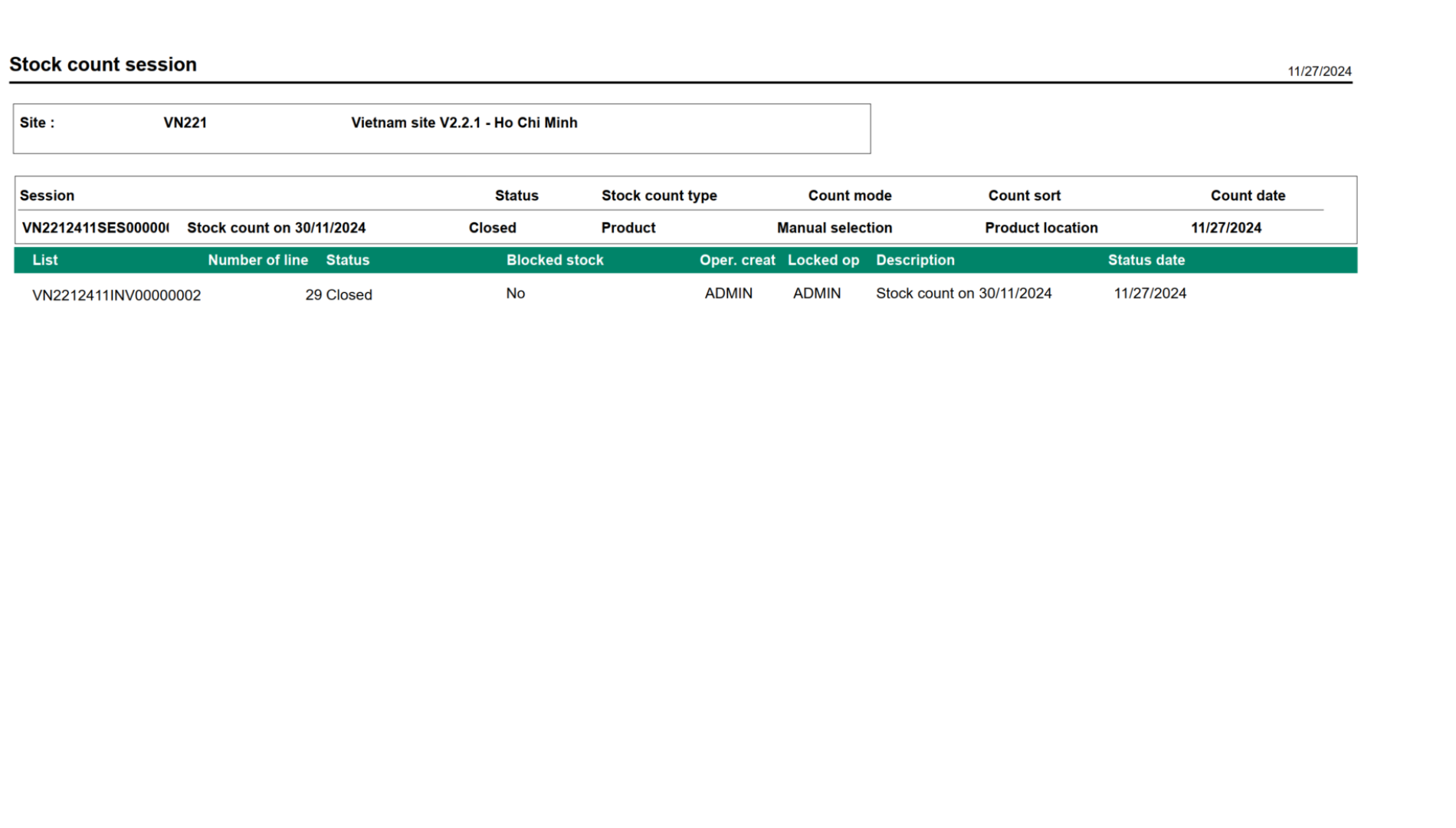

- Create Stock Counting Sessions: From the Inventory Management module, create a new session linked to your counting plan. This session will track the progress and results of the count.

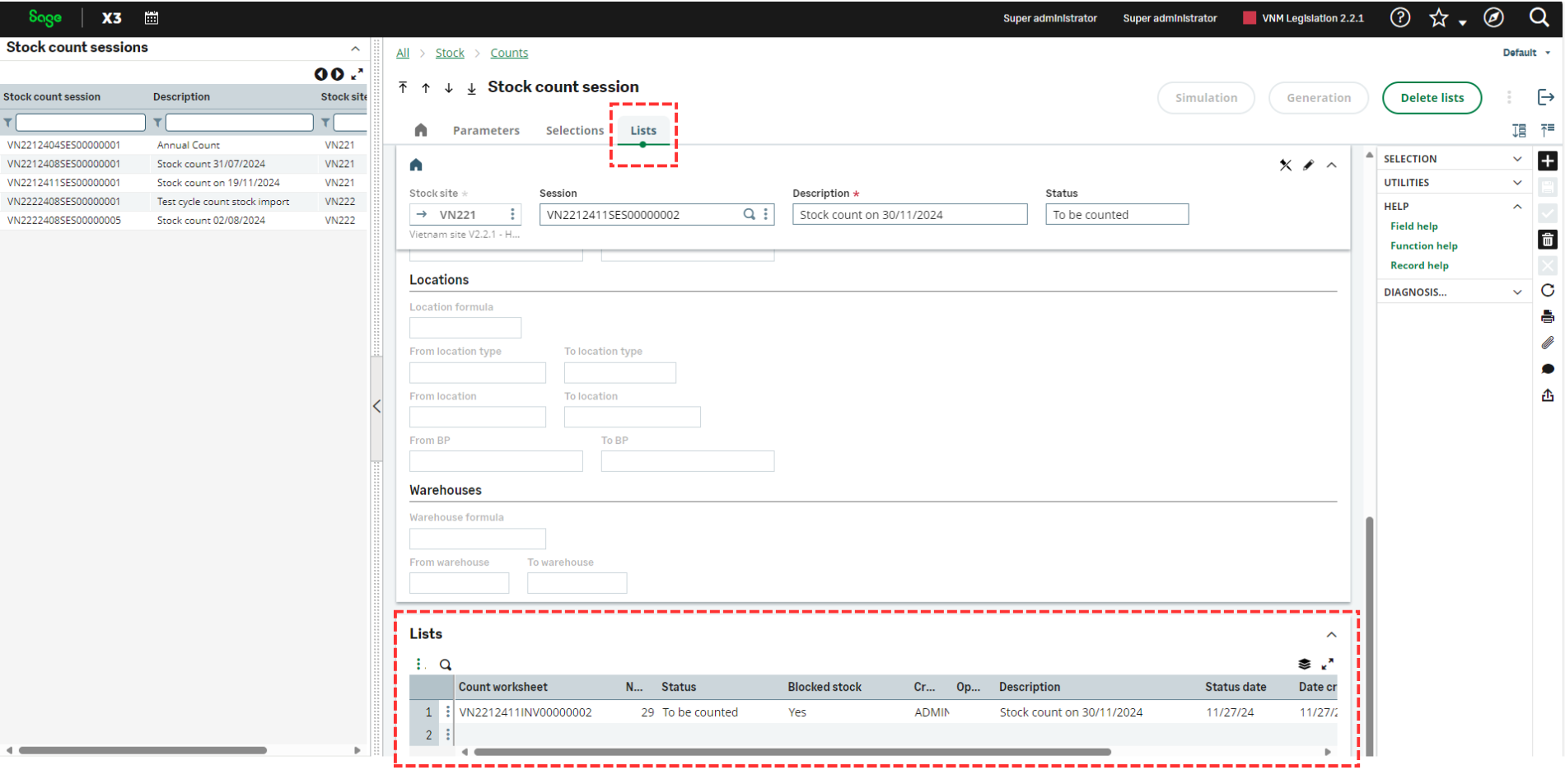

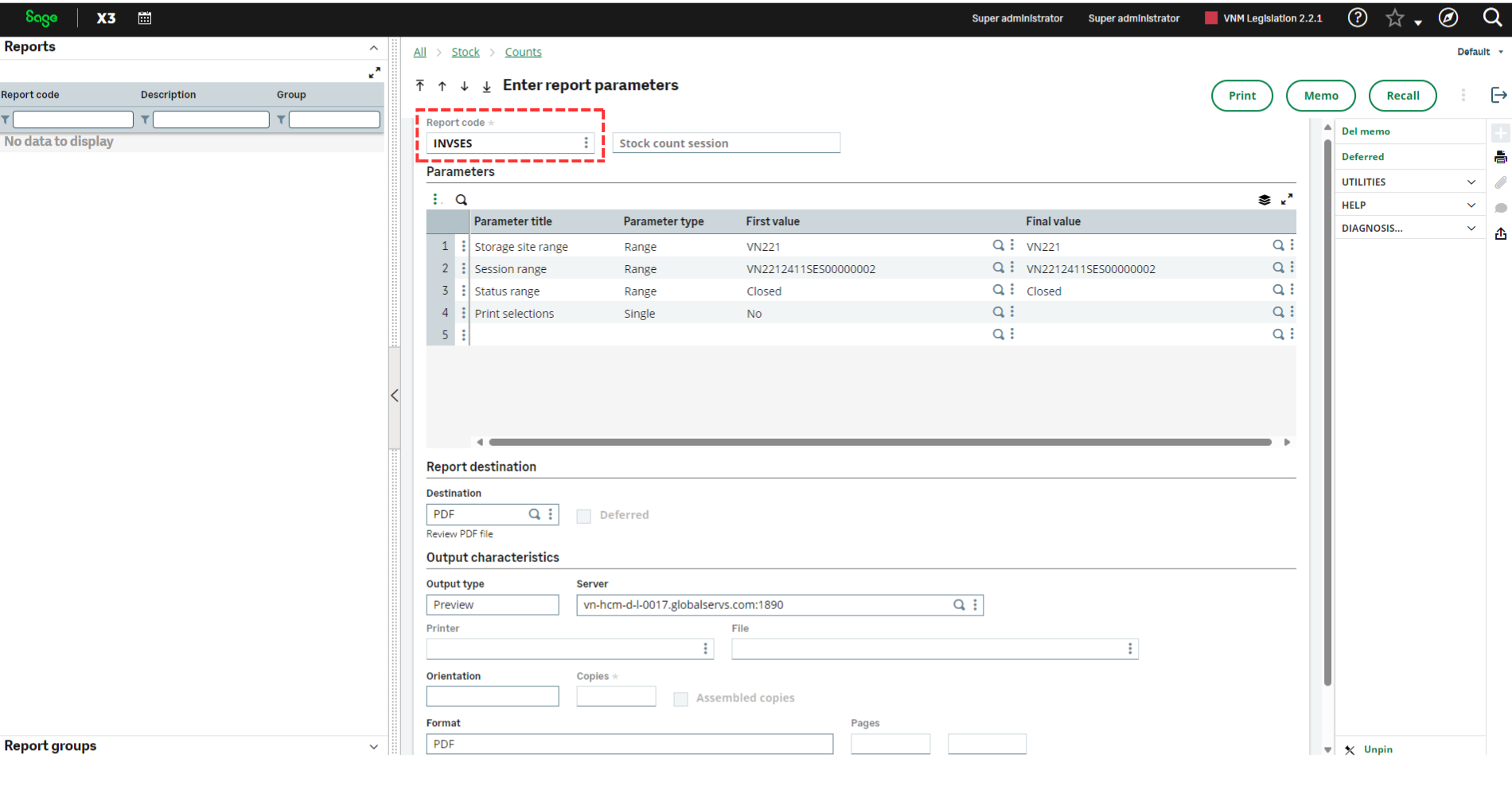

- Generate Counting Lists: Sage X3 allows you to generate pre-printed counting lists based on your plan. These lists can be assigned to specific teams or individuals.

3. Conduct the Physical Count:

- Count and Record: Teams physically count the stock and record the quantities on the counting lists or directly into mobile devices if using a barcode scanning system integrated with Sage X3.

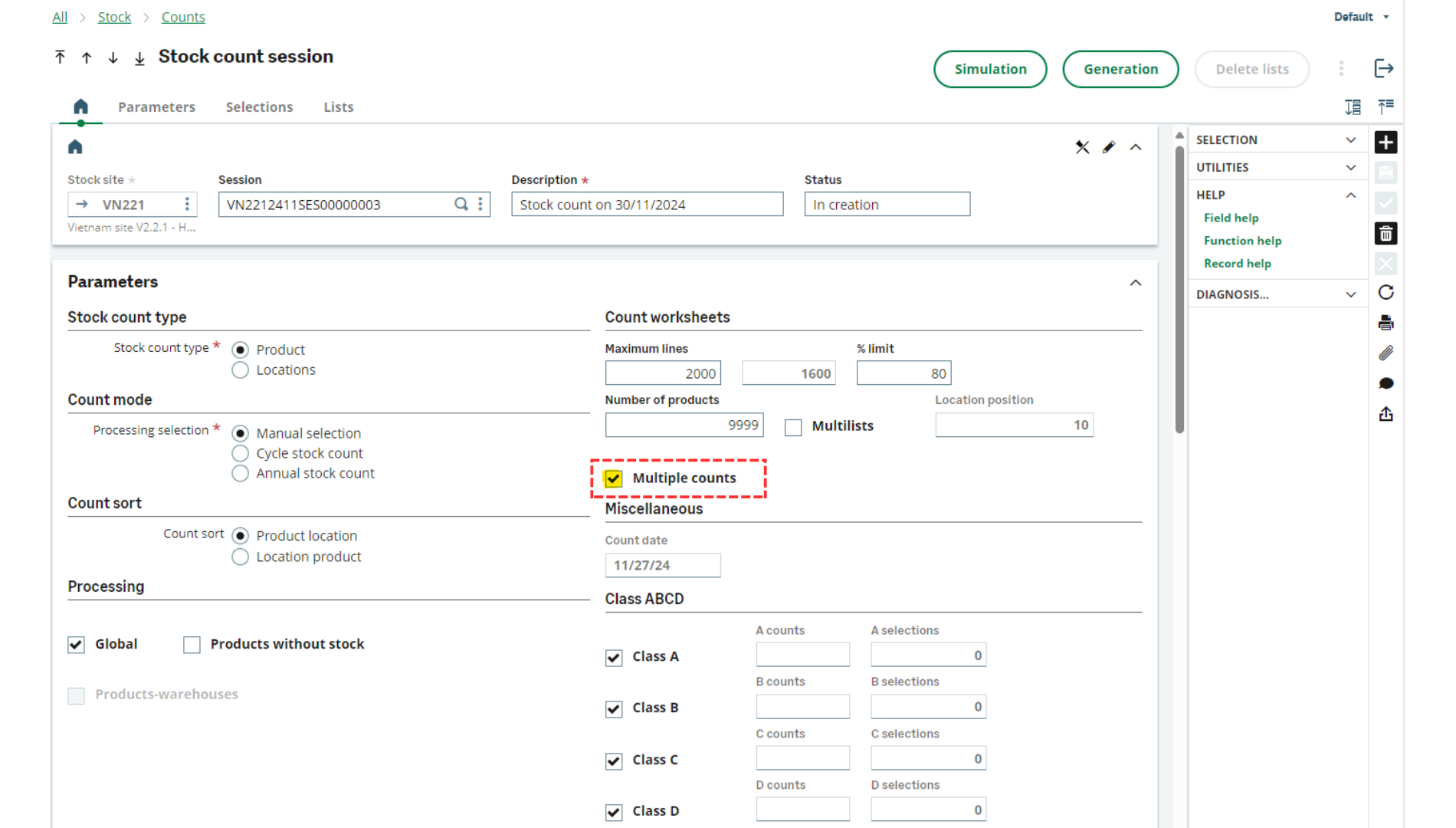

- Multiple Counts: For increased accuracy, consider implementing a double-counting process where two independent teams count the same items.

- Address Discrepancies: If initial counts differ, teams should recount to resolve the discrepancies.

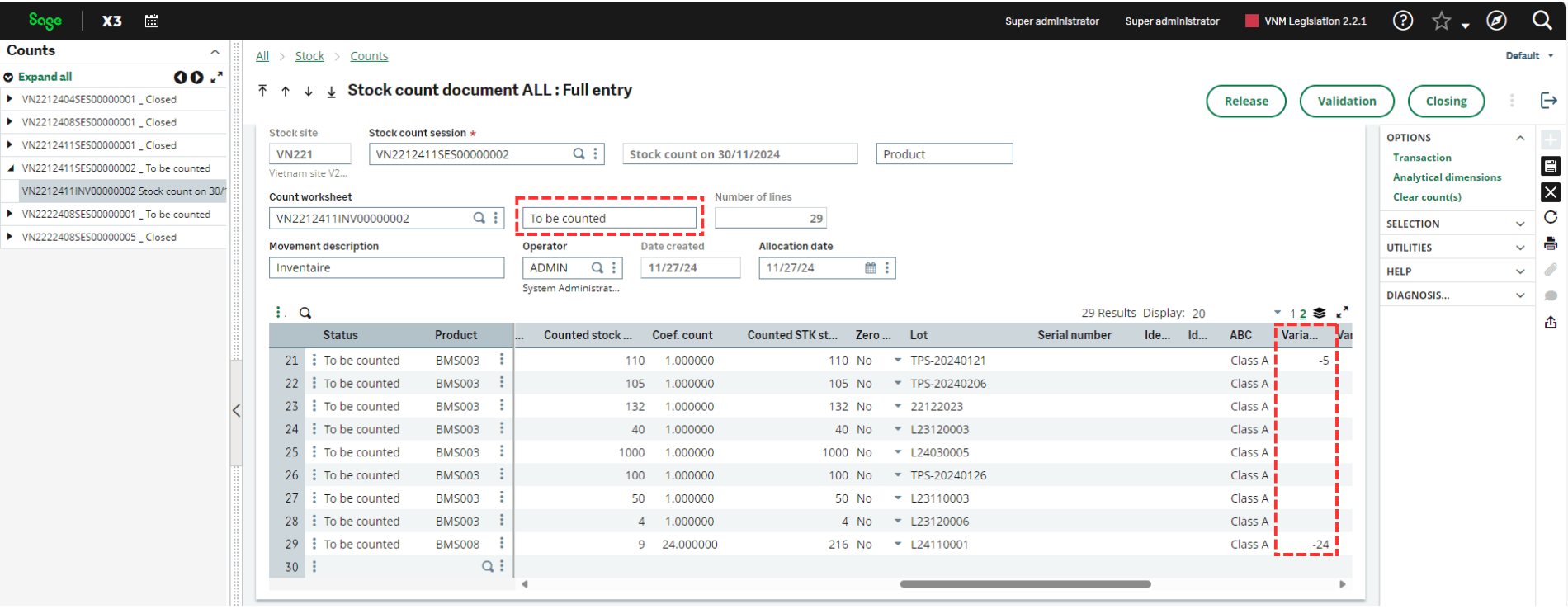

4. Enter Counts into Sage X3:

- Manual Entry: If using paper lists, the counted quantities are manually entered into the system.

- Import from Scanners: If using barcode scanners, the data can often be directly imported into the stock counting session.

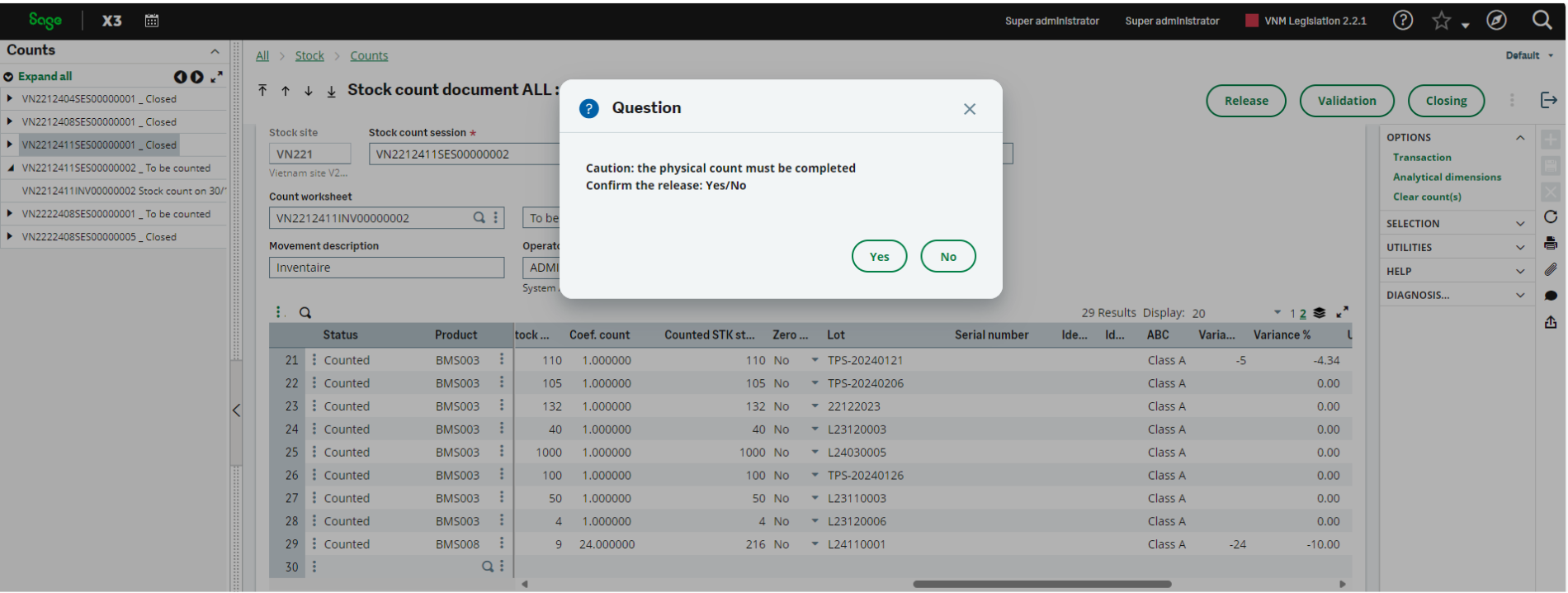

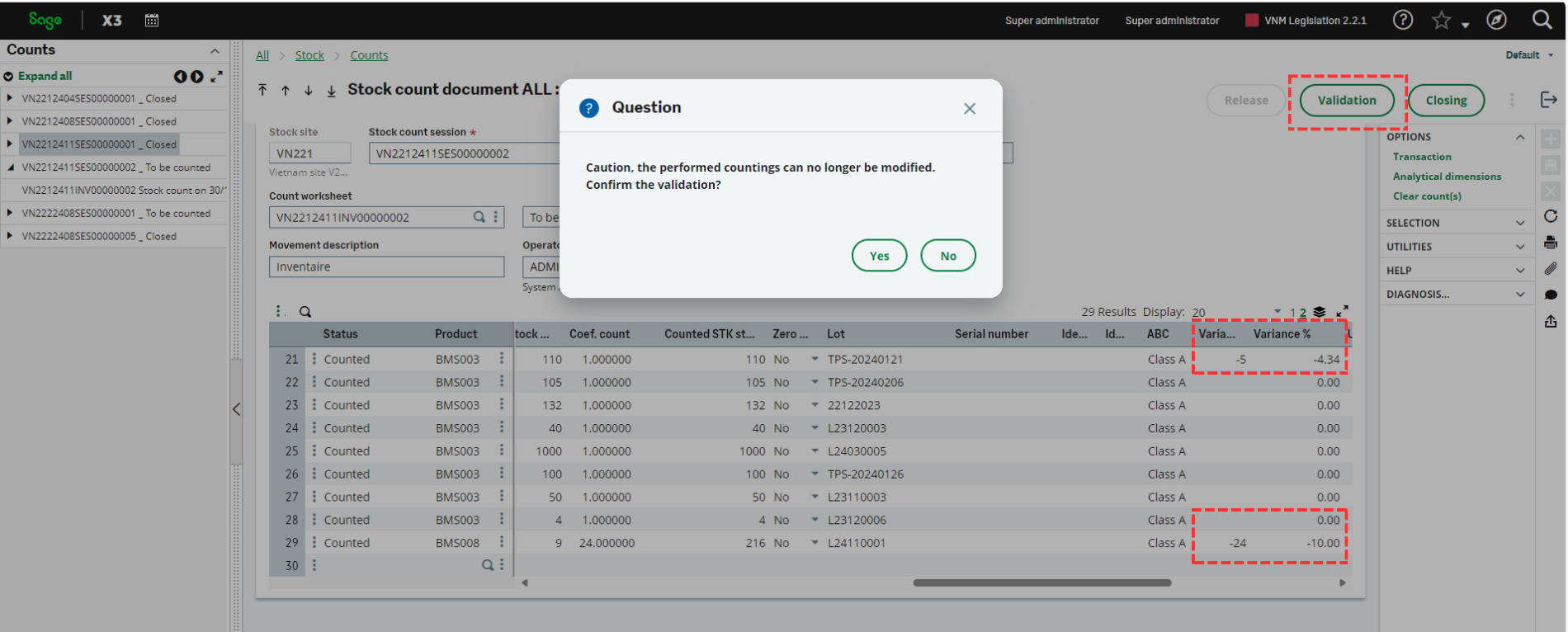

5. Validate and Reconcile:

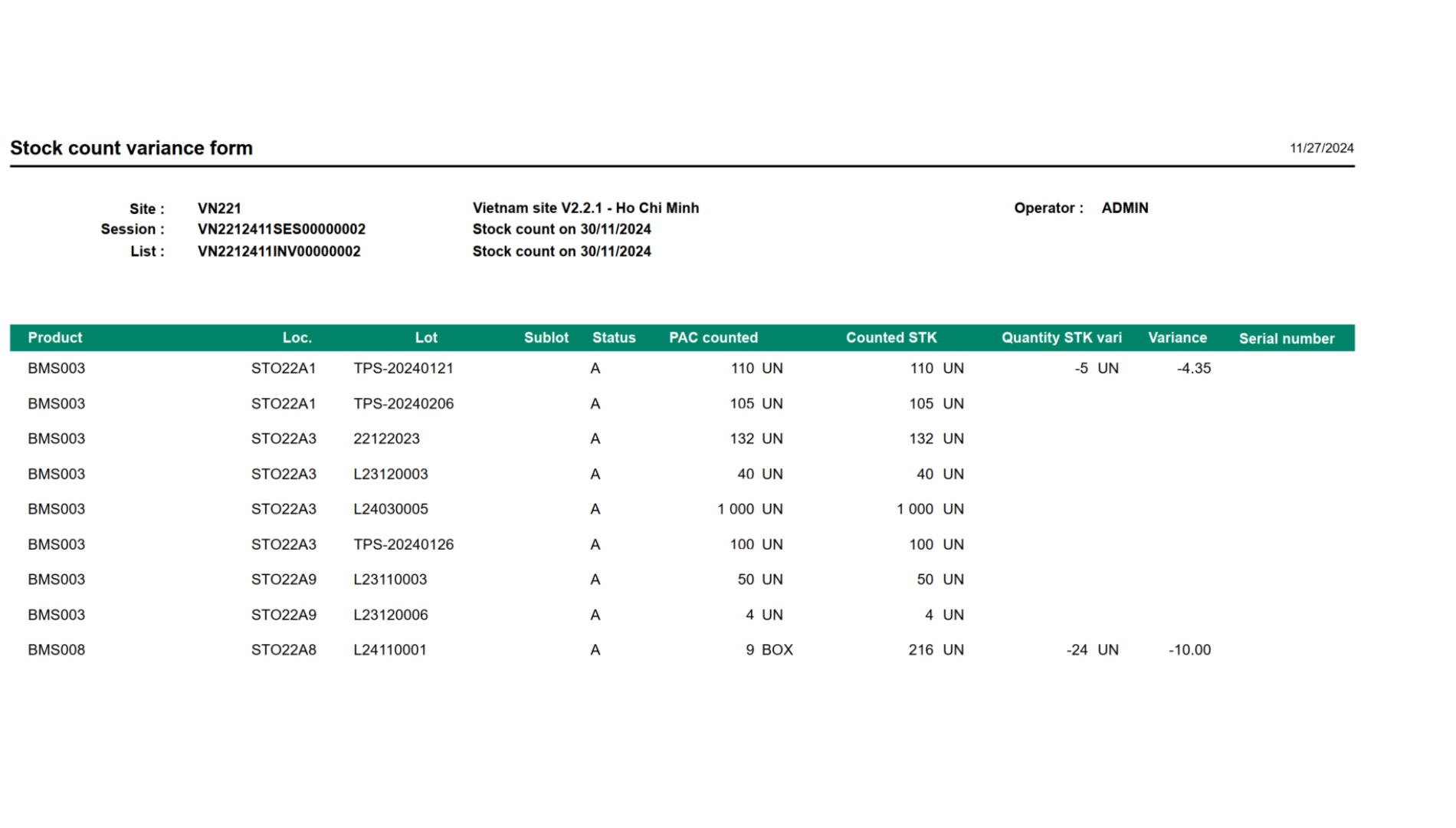

- Review Counts: Sage X3 provides tools to compare the counted quantities with the system’s recorded quantities.

- Investigate Variances: Analyze any significant discrepancies between the physical count and the system data. Common reasons for variances include:

- Data entry errors

- Misplaced items

- Inaccurate transactions in the system

- Theft or shrinkage

- Adjust Stock Levels: Once variances are investigated and resolved, you can use Sage X3 to adjust the stock levels to reflect the actual count.

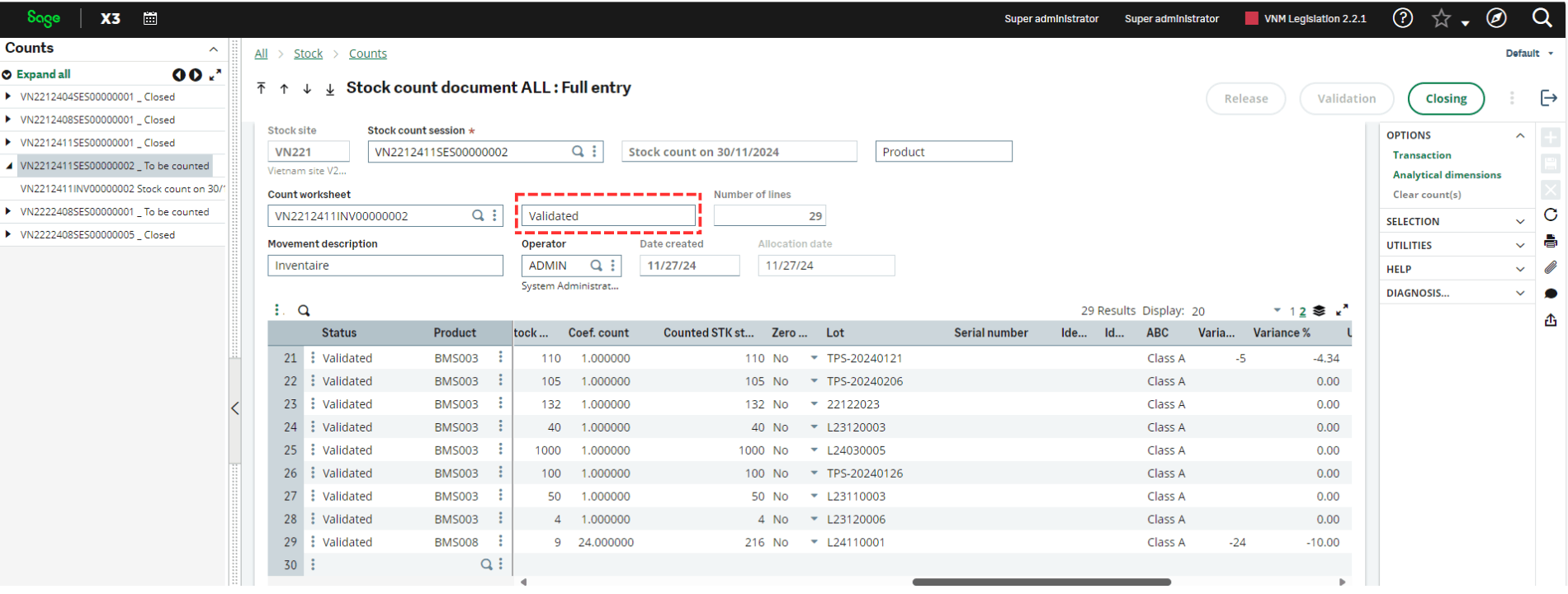

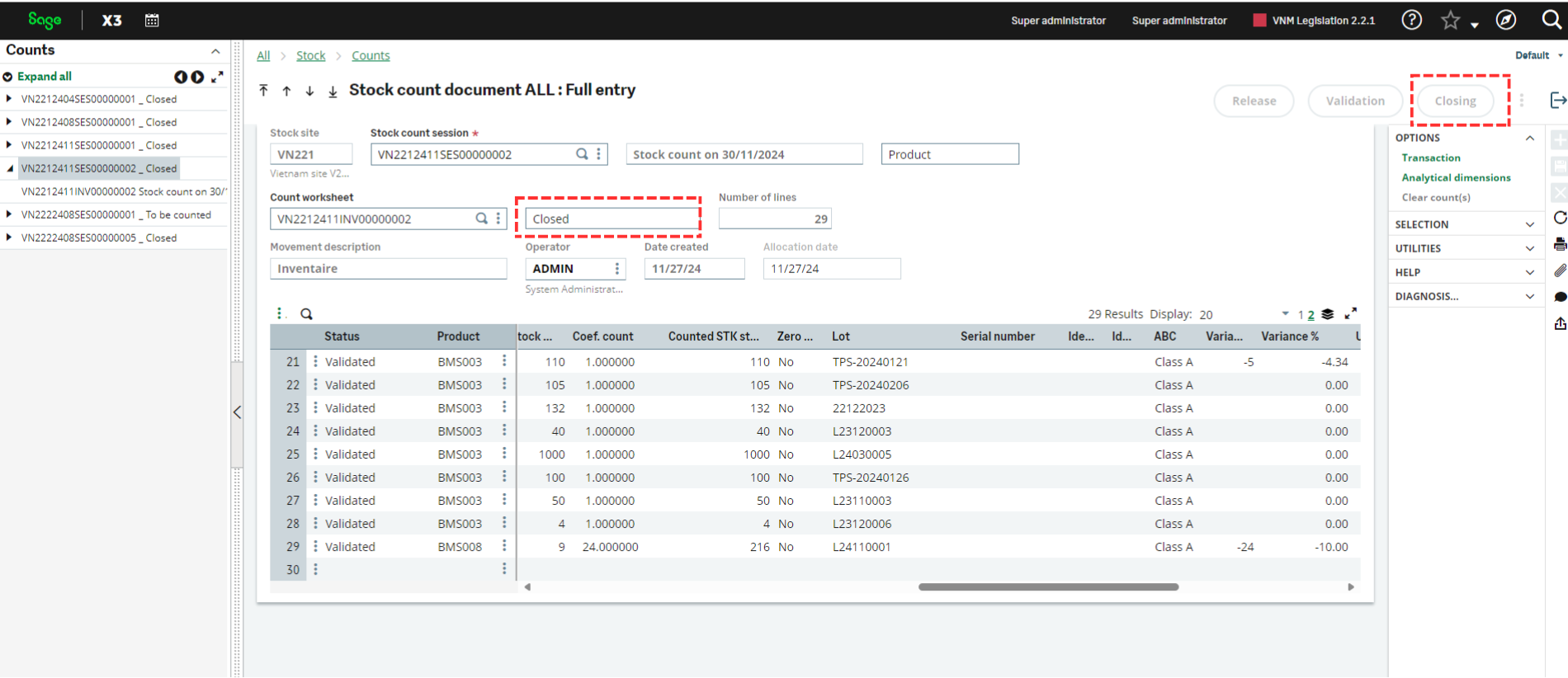

6. Close the Stock Counting Session:

- Finalize the Count: After all adjustments are made and validated, close the stock counting session in Sage X3. This confirms the completion of the process.

7. Reports:

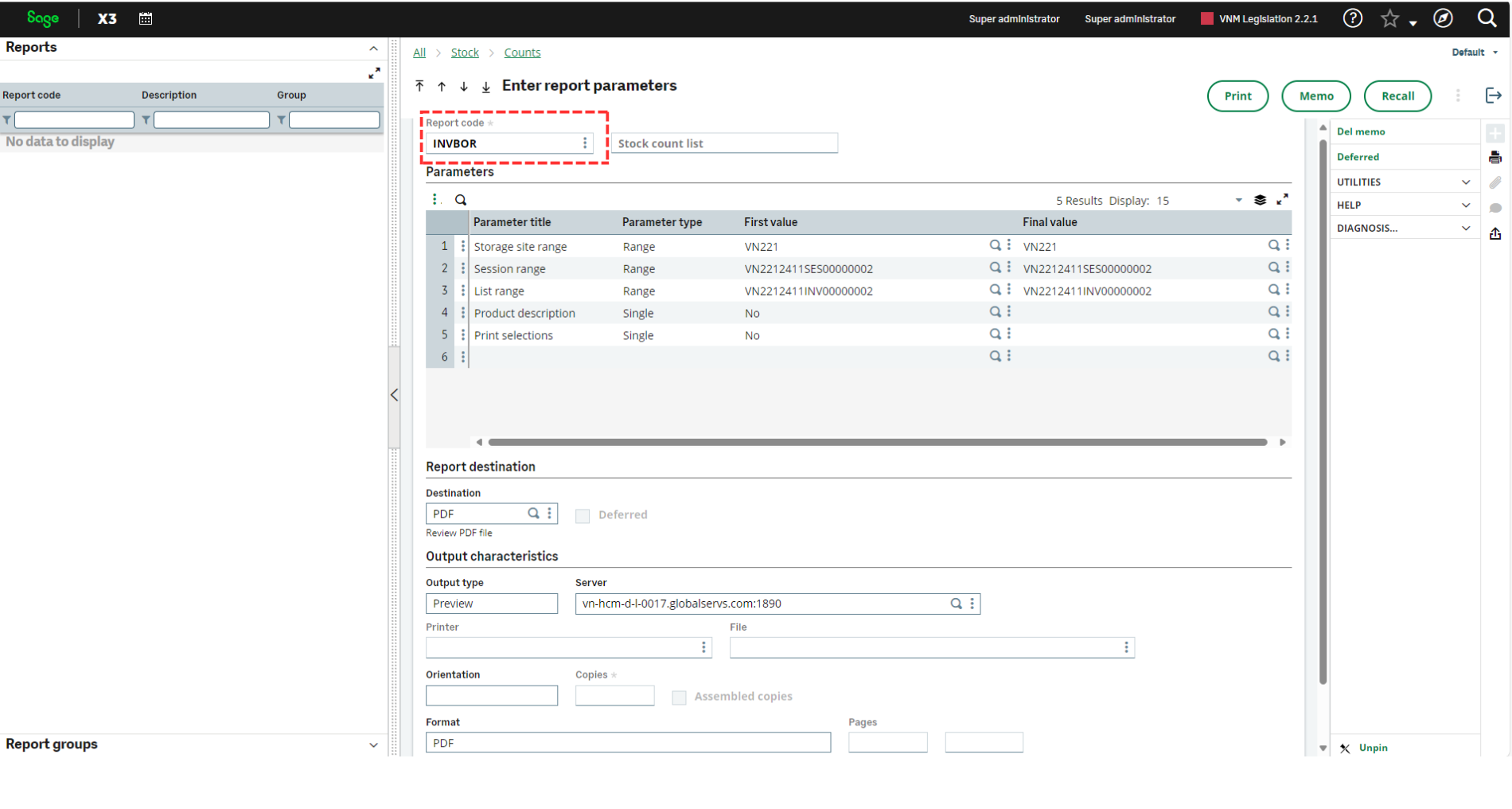

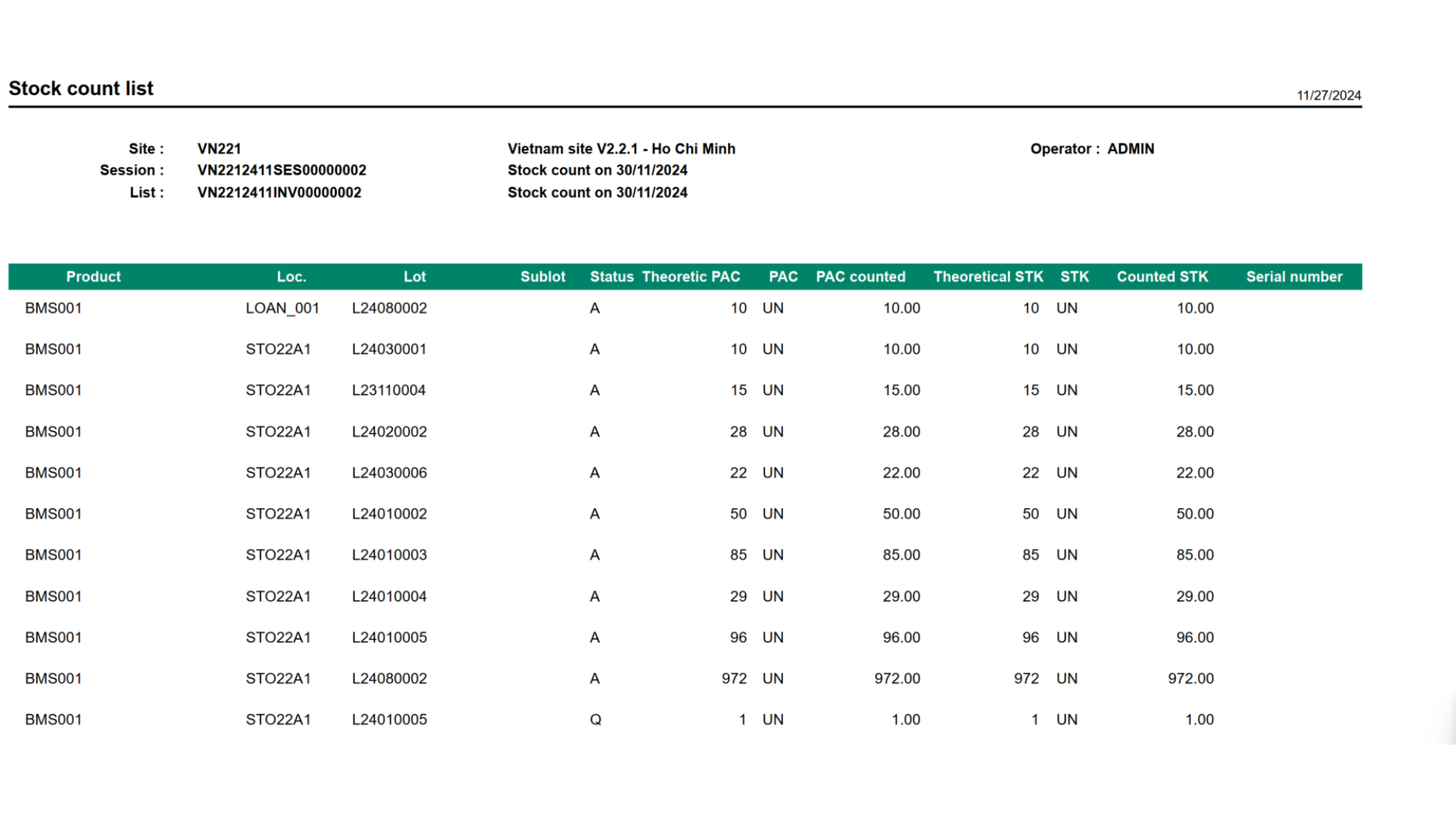

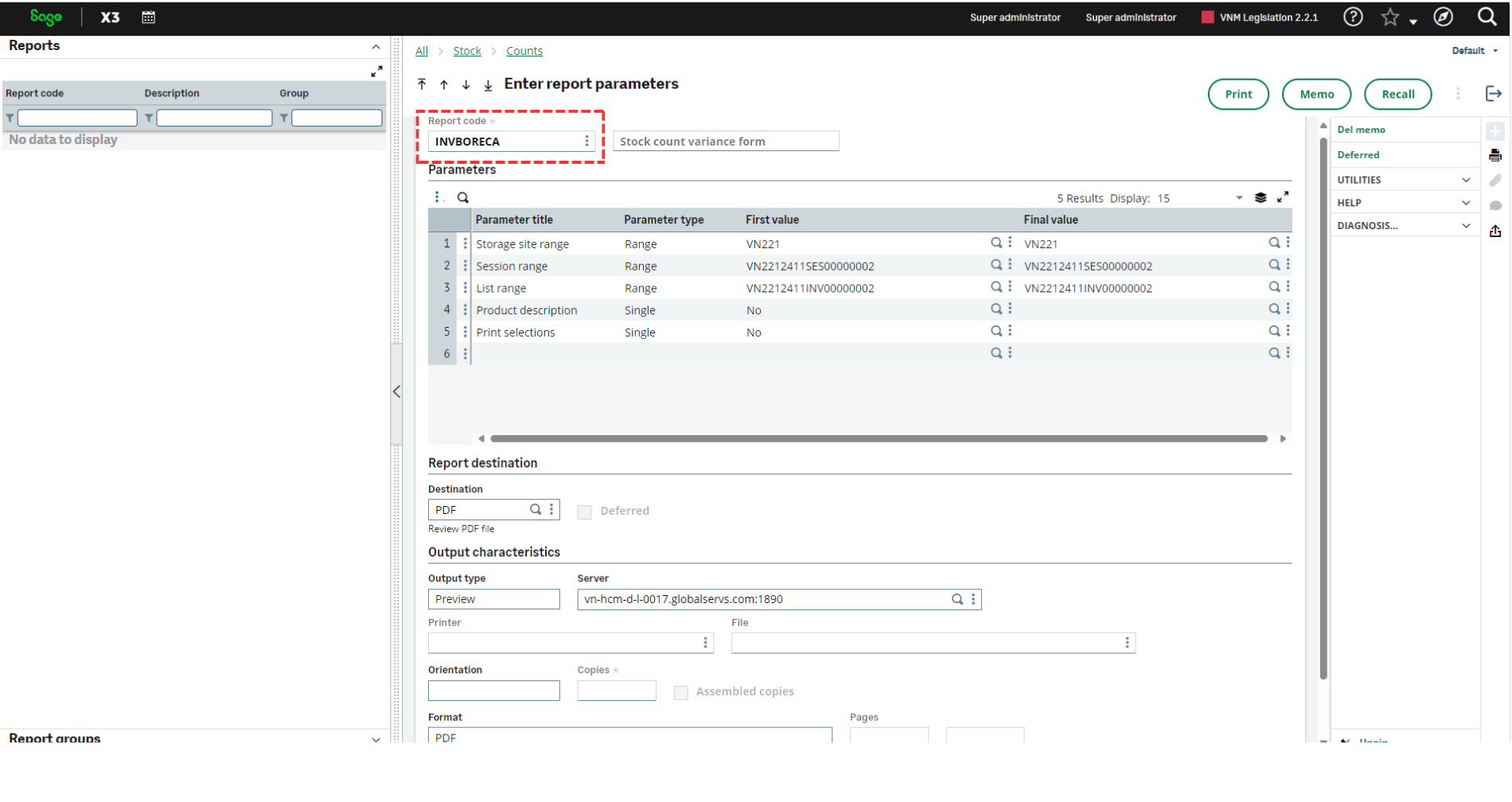

By default, the following reports are associated with this function :

- INVBOR : Stock count list

- INVBORECA: Stock count variance form

- INVSES : Stock count session

The reports can be changed using a different setup.

Tips for Efficient Stocktaking with Sage X3:

- Utilize Mobile Devices: Integrating barcode scanners or mobile devices with Sage X3 can significantly improve efficiency and reduce errors.

- Regular Cycle Counting: Implement a cycle counting program to count specific items regularly throughout the year, reducing the need for full physical inventories.

- Analyze Stocktaking Results: Regularly review the results of your stock counts to identify trends, problem areas, or potential improvements in inventory management.

By following these steps and utilizing the features of Sage X3, you can ensure accurate stock data, improve inventory control, and enhance the overall efficiency of your operations.

Need help with your Sage X3 implementation or looking to optimize your existing system?

Ekino Vietnam is an official partner of Sage X3, with a team of certified consultants and developers ready to assist you. We offer a comprehensive range of services, including:

- Implementation: Get your Sage X3 system up and running smoothly with our expert guidance.

- Add-on Development: Customize your Sage X3 solution to meet your unique business needs.

- Training: Empower your team with the knowledge and skills to effectively use Sage X3.

- Upgrading: Stay current with the latest Sage X3 features and functionalities.

Contact Ekino Vietnam today at contact@ekino.vn to learn more about how we can help you maximize the value of your Sage X3 investment.